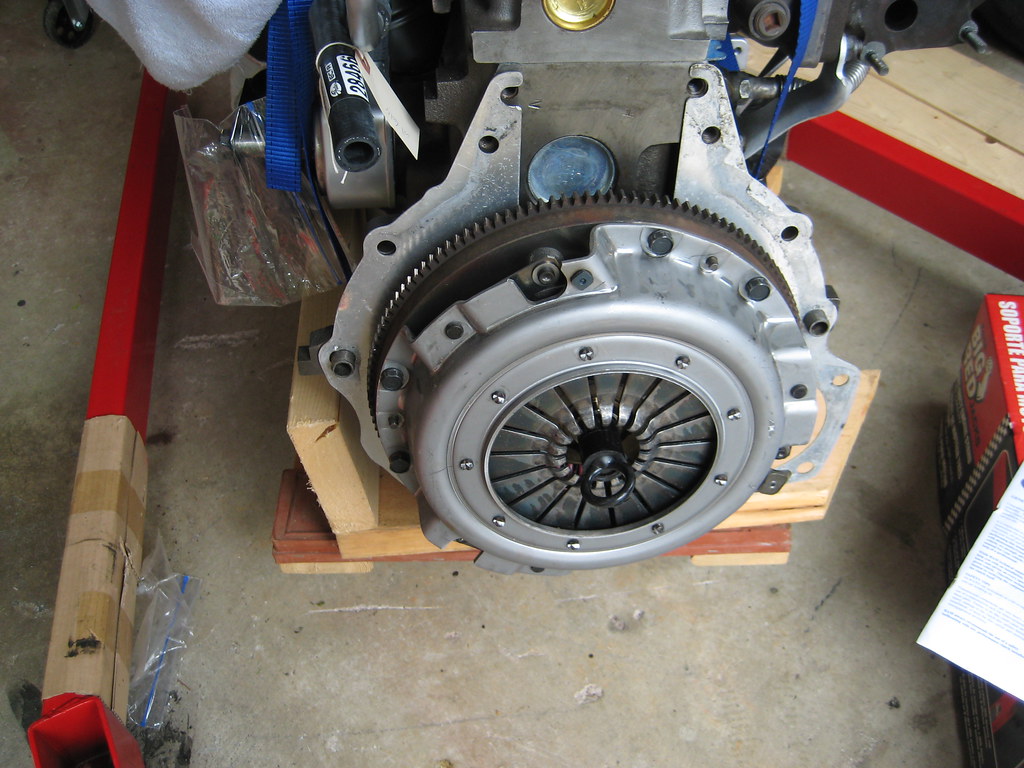

So I installed a few things on the engine (tensioners, upper intake, oil dipstick etc.) then started on the EEC wiring harness. I was originally going to use the 89 xr4ti harness I got with the third motor, but there turned out to be enough differences that I decided to use it as parts for the 84 or 85 harness I got off eBay years ago.

I think I replaced every connector. Wow 30 year old wiring sucks!

Here is all that I replaced:

Three things left to do before installing all the harnesses:

1. figure out how to position the EEC wires so I can wrap them (anyone with a picture of an 84 RS Turbo/GT Turbo/SVO harness out of the car?)

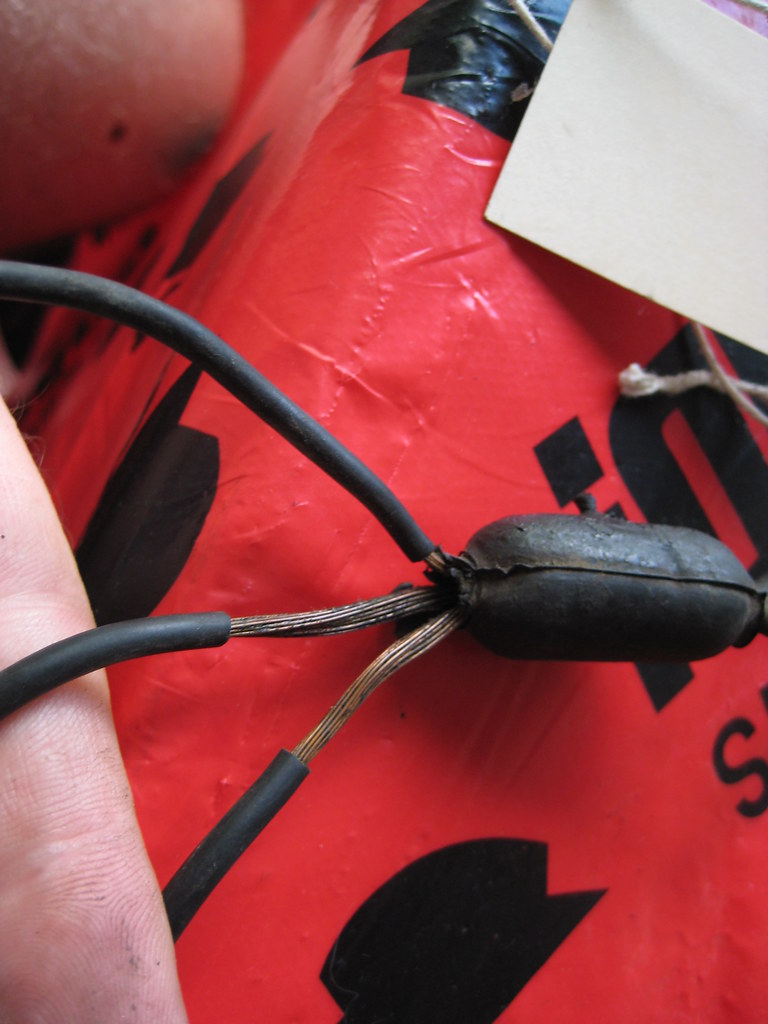

2. Figure out how to fix this:

3. And this: